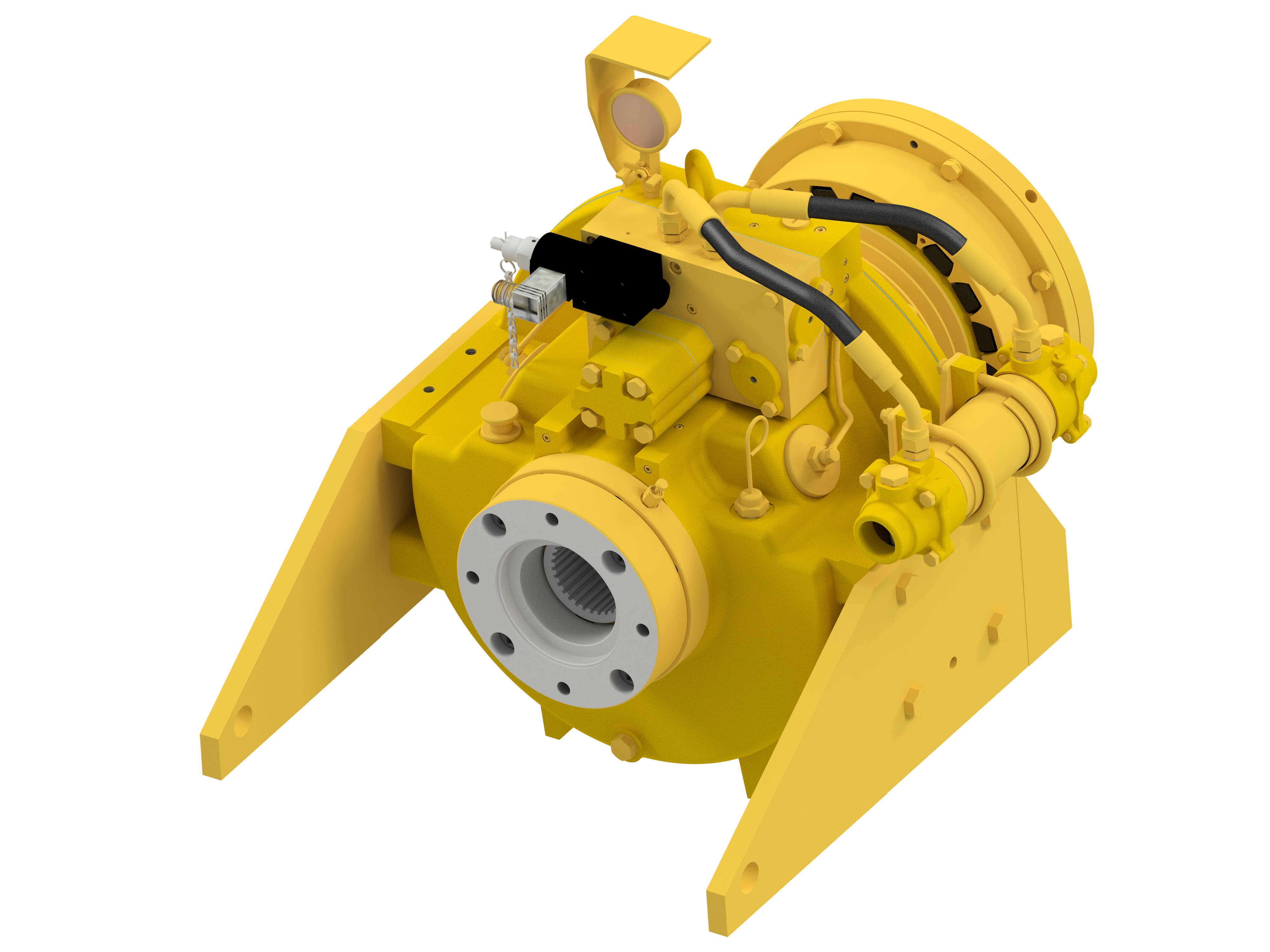

Key feature

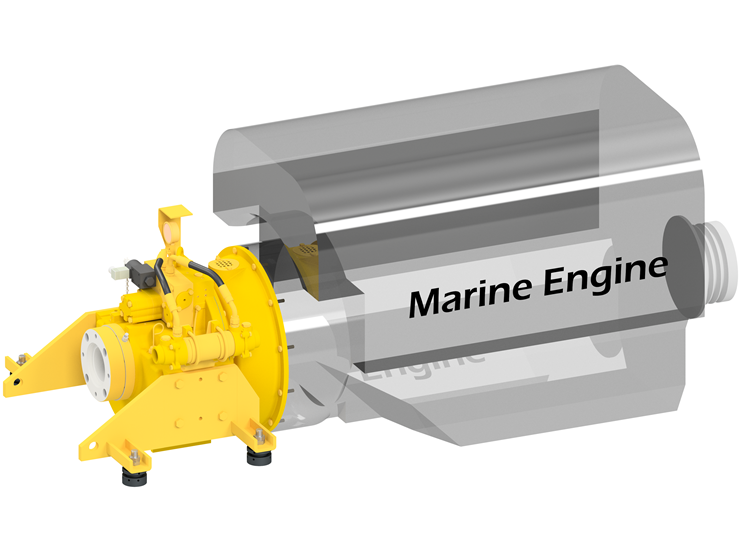

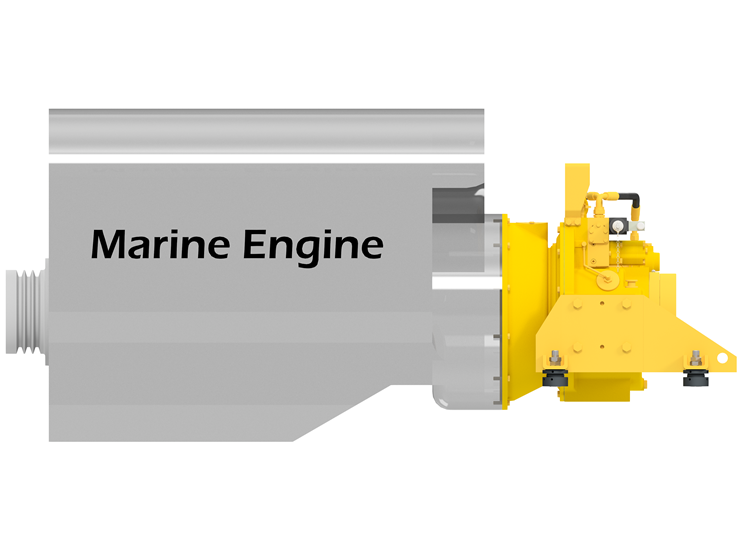

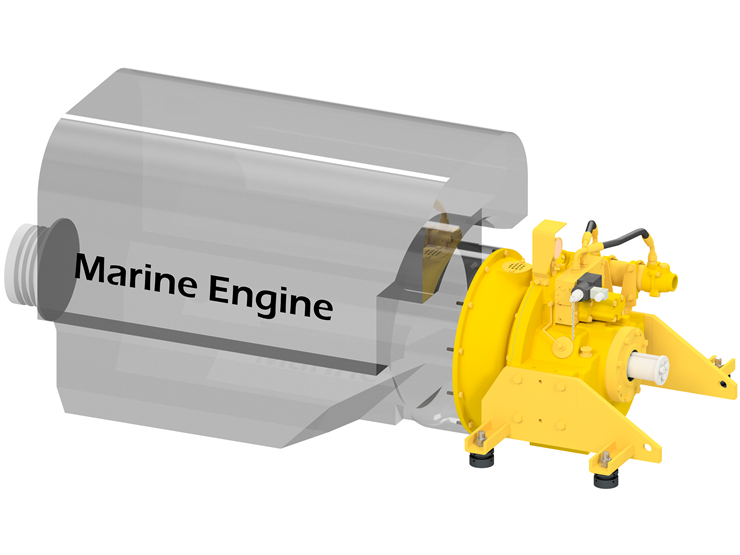

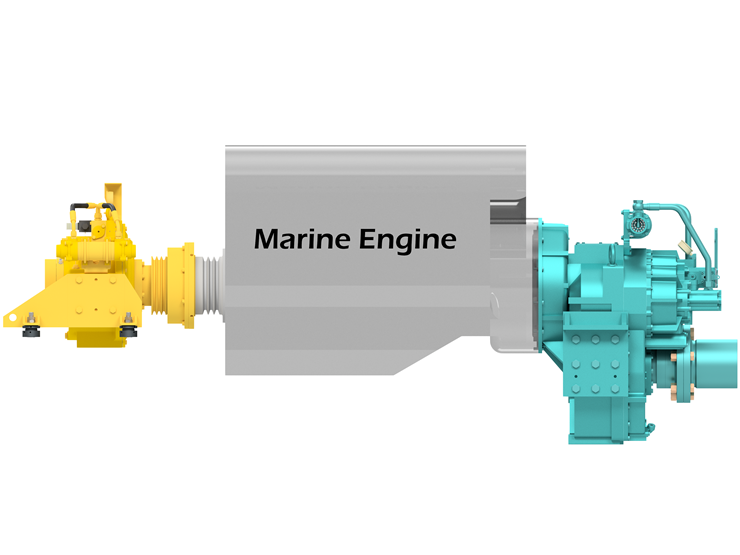

– Attachable for both side of front(pulley) and rear(bell housing) of the engine

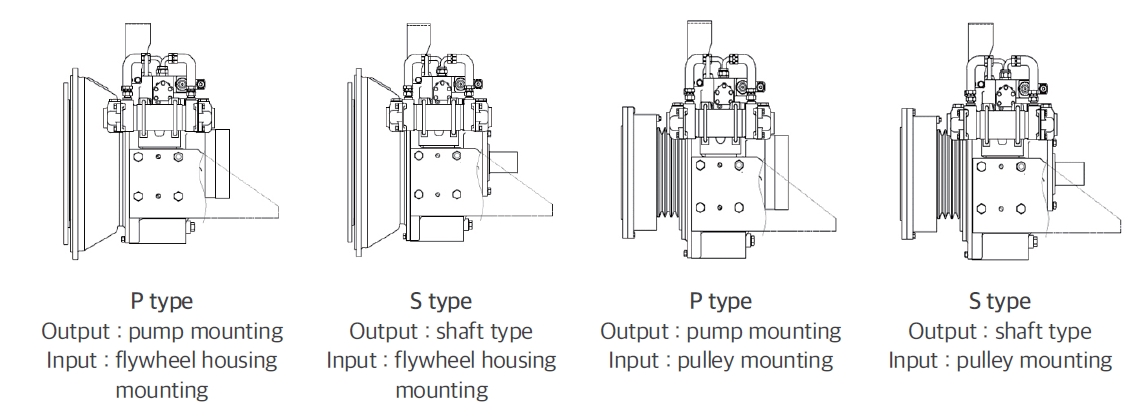

– Versatility of Output types

– Continuous running PTO(9″, C type, 3 grooves)

– Perfect brake system to prevent dragging

– Pressure gauge provided as standard

– Monitoring function to see rotate in case of pump attachment

– Anode zinc on oil cooler prevent the corrosion

– Easy removal metal in oil with Magnet plug

– Compatible Pump Pad to various pumps

(If required, machining is needed)

Install for

Drive for hydraulic pump(Side thruster, work craft, crane etc)

Drive for pulley(hydraulic winch, Generator, Air compressor, Sea water pump, etc)

Anywhere needs to power train

Options

– Control box

– Pump Mounting Kit

– Bell Housing (SAE#1, 2)

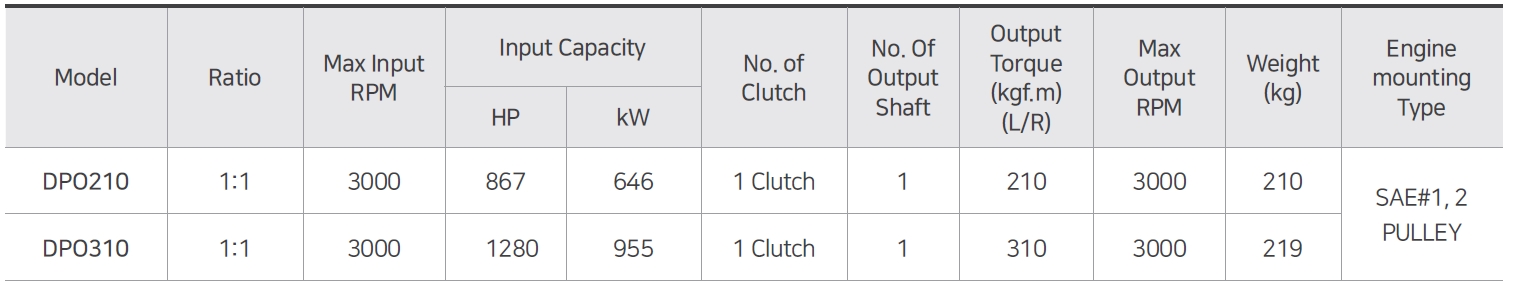

Capacity Table

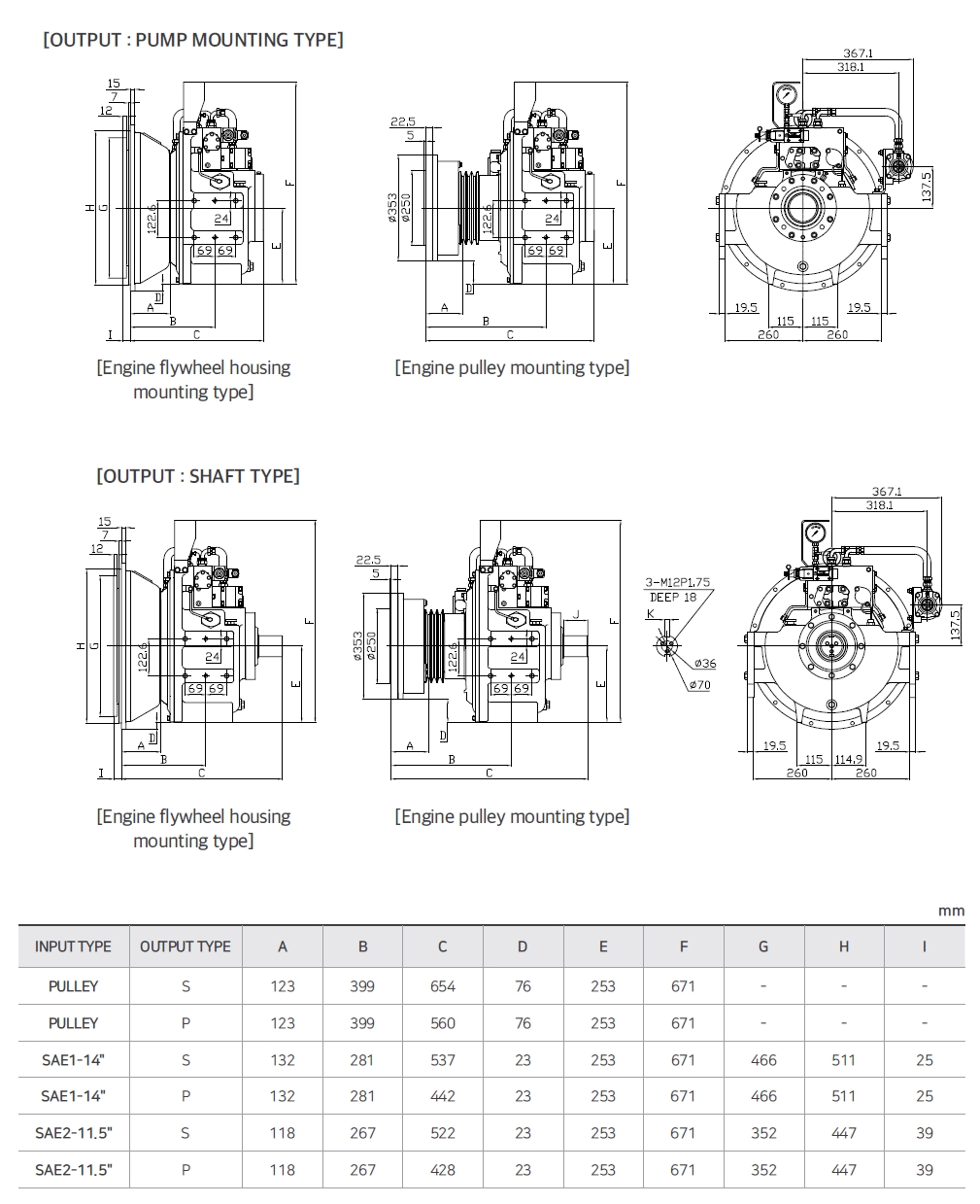

Dimension

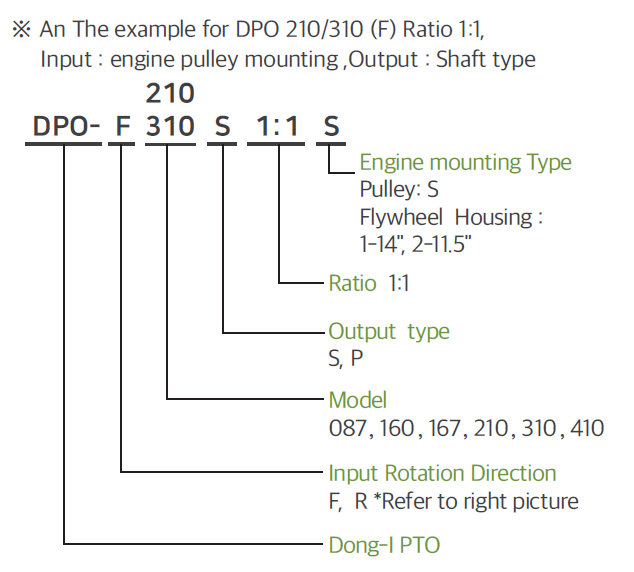

Order Code Configuration

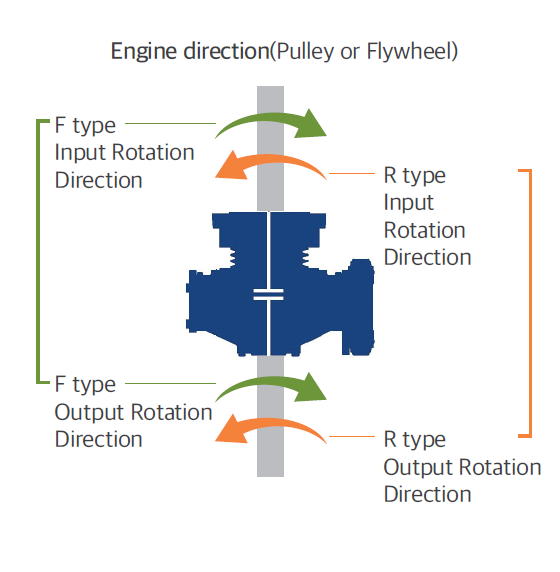

Rotation Direction Type

Output Types

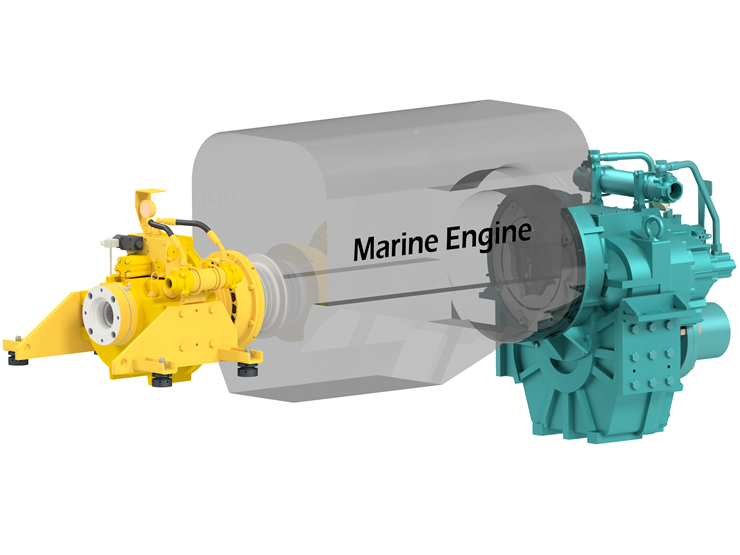

Mounting Example _ Main engine pulley mounting type

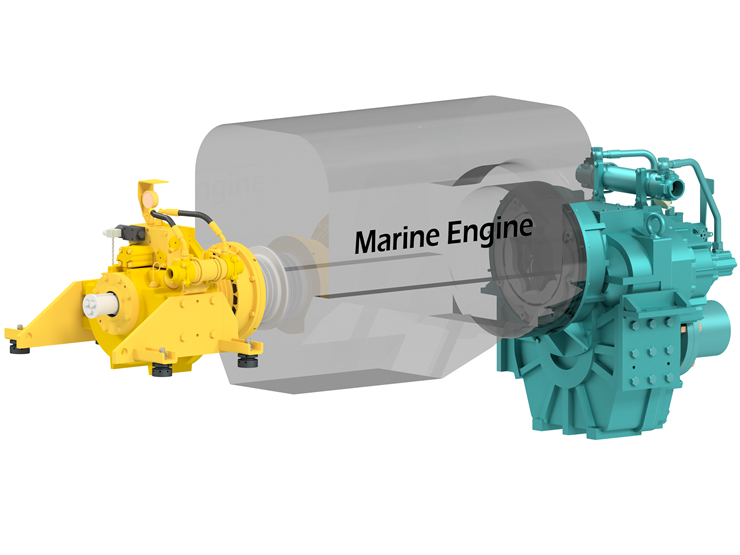

Mounting Example _ Auxiliary engine flywheel mounting type