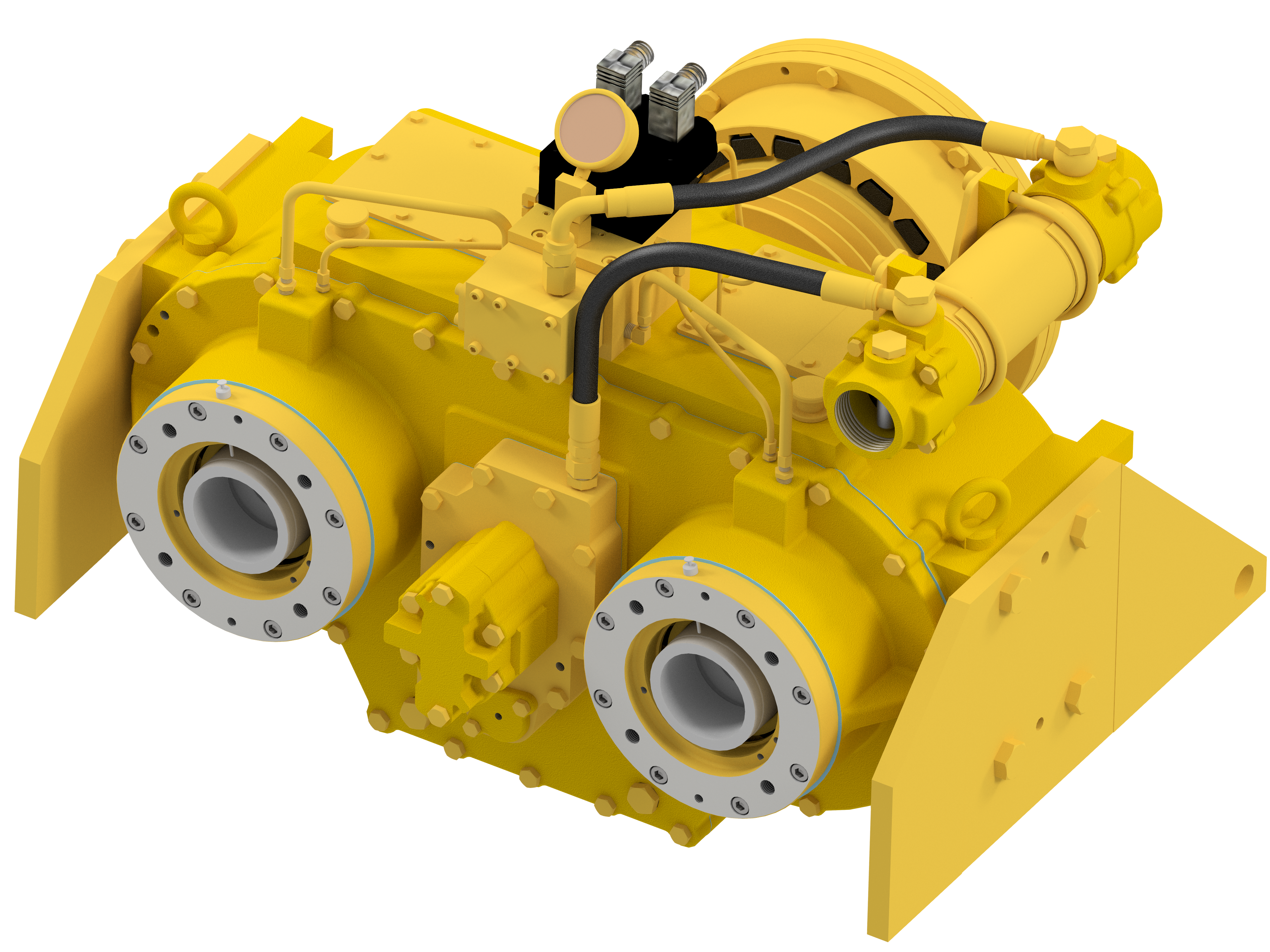

Key features

– Attachable for both side of front(pulley) and rear(bell housing) of the engine

– Independent control by 2 clutches

– Live pulley provided(7″, B type, 2 grooves)

– Perfect brake system to prevent dragging

– Zinc anode on oil cooler prevent the corrosion

– Monitoring function to see rotation of pump shaft

– Pressure gauge provided as standard

– Easy removal metal in oil with Magnet plug

– Compatible Pump Pad to various pumps (If required, machining is needed)

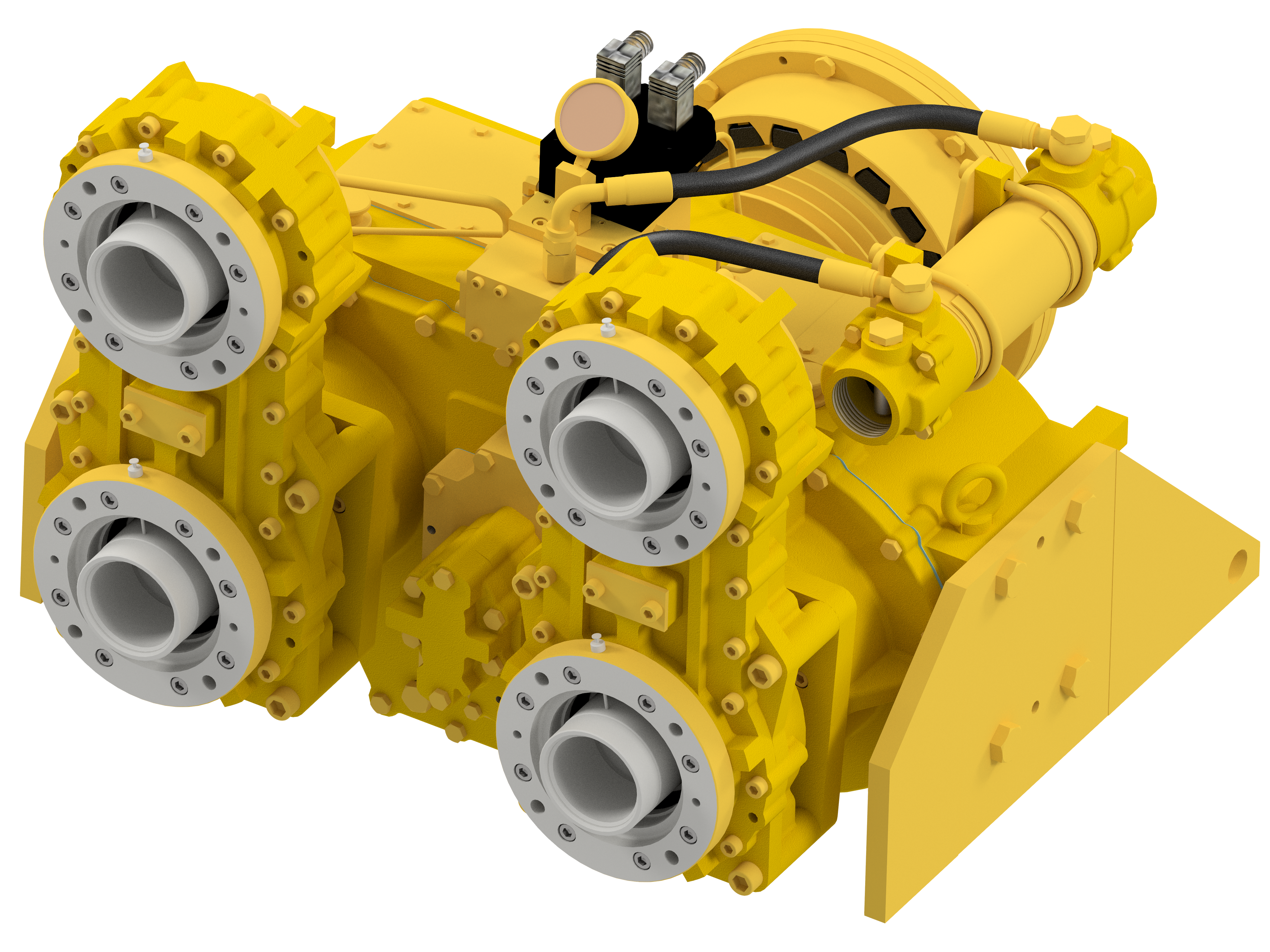

– Extendable 2 output ports each with gear box installation(Option)

Install for

– Drive for hydraulic pump(Side thruster, work craft, crane, etc)

– Pulley (Hydraulic winch, Generator, Air compressor, Sea water pump, etc)

– Anywhere you need to use devices for power train

Options

– Control box

– Pump Mounting Kit

– Bell Housing (SAE#1, 2)

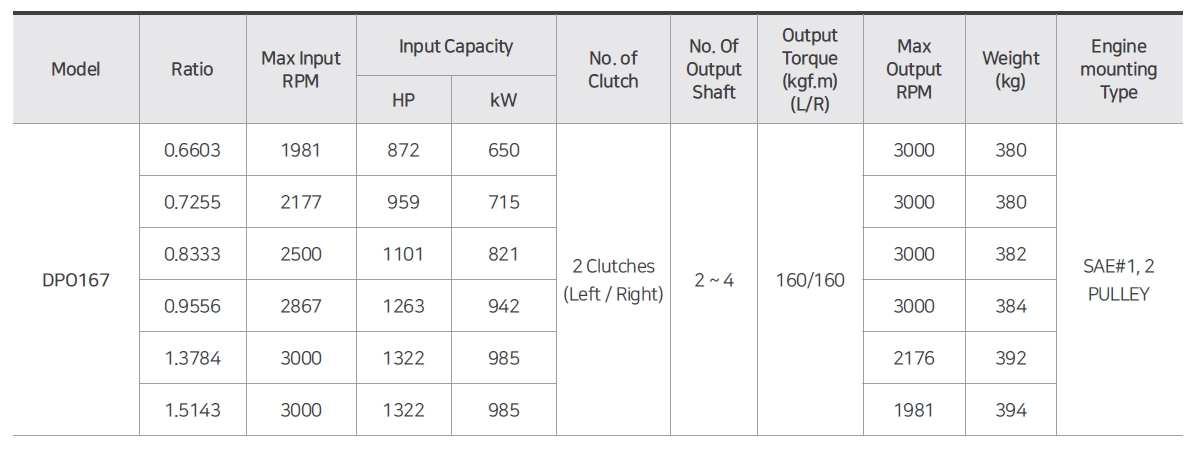

Capacity Table

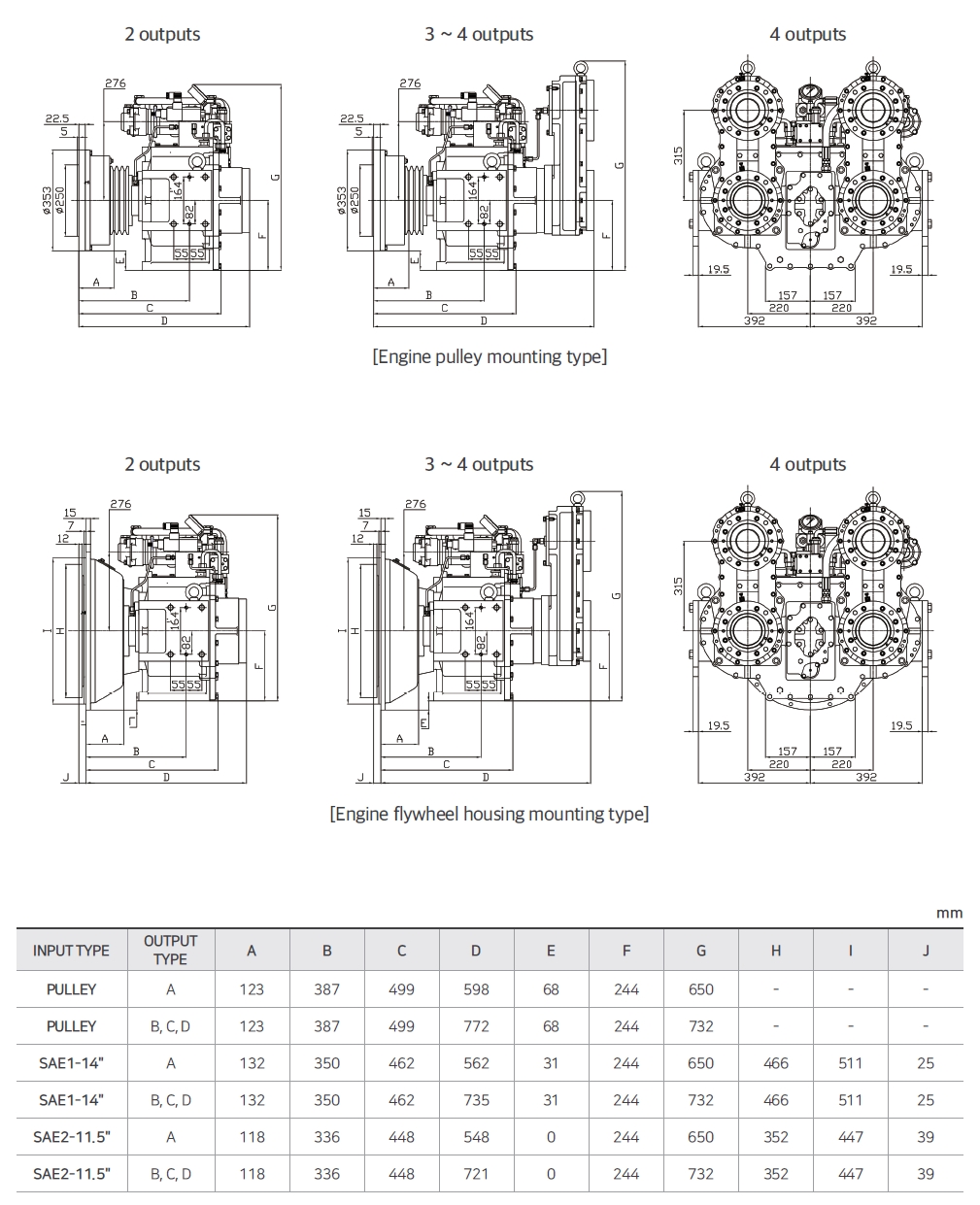

Dimension

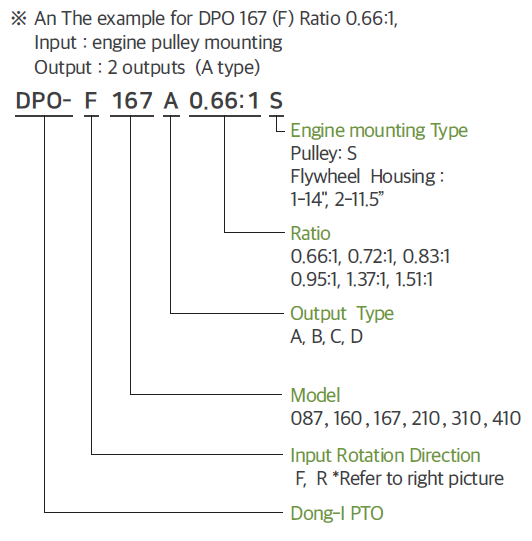

Order Code Configuration

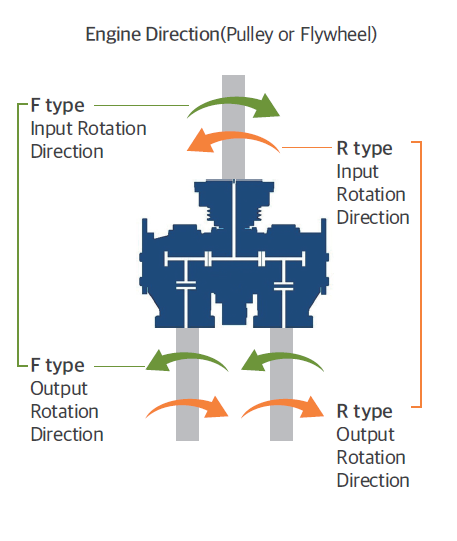

Rotation Direction Type

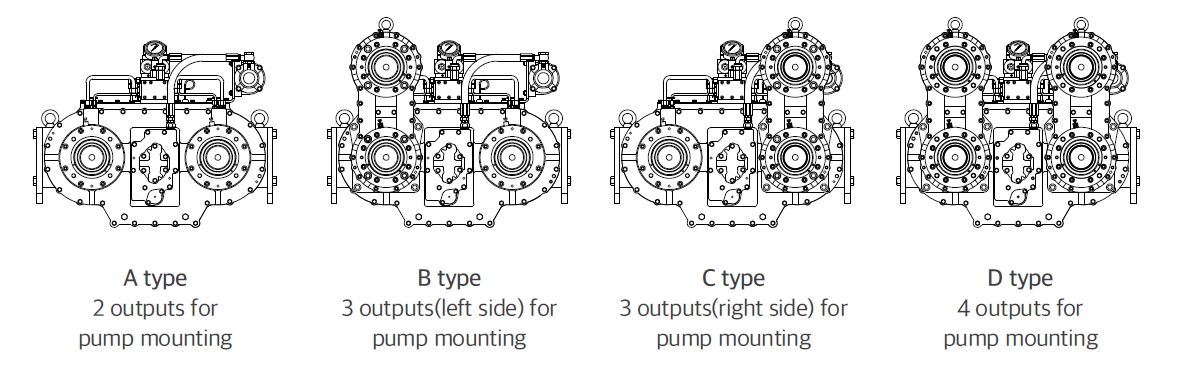

Output Types

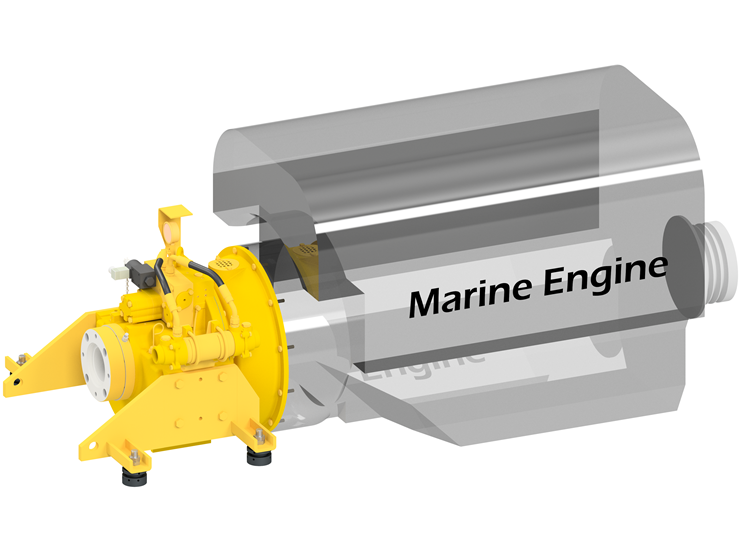

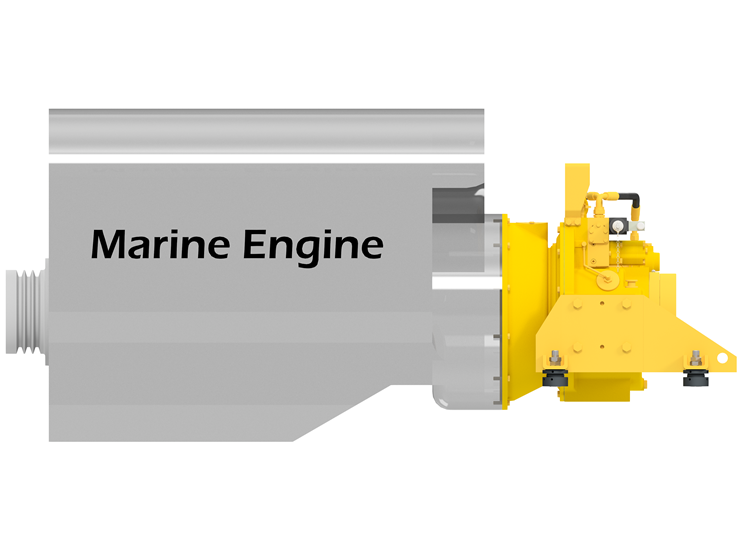

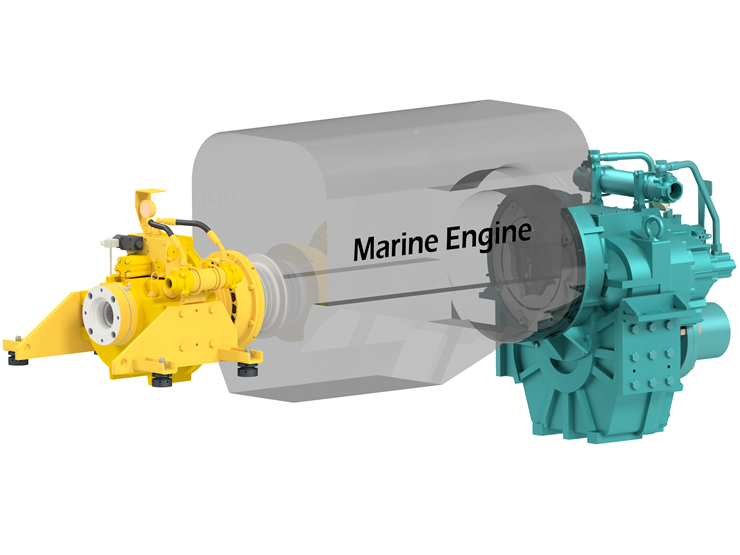

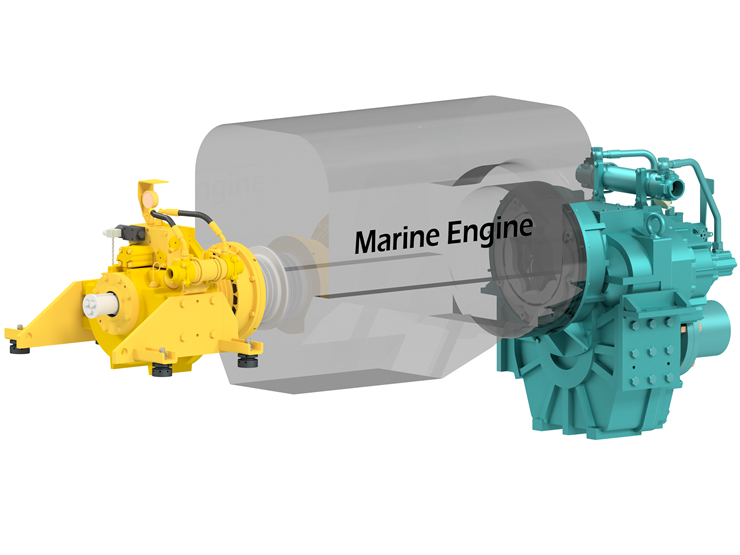

Mounting Example _ Main engine pulley mounting type

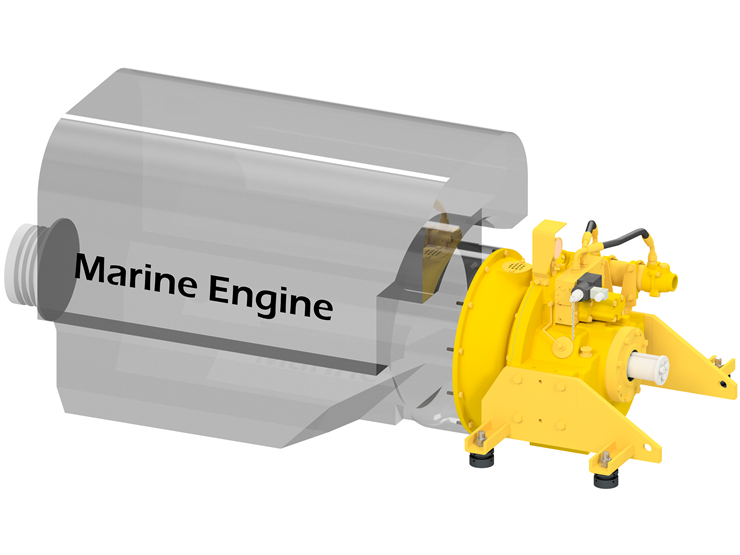

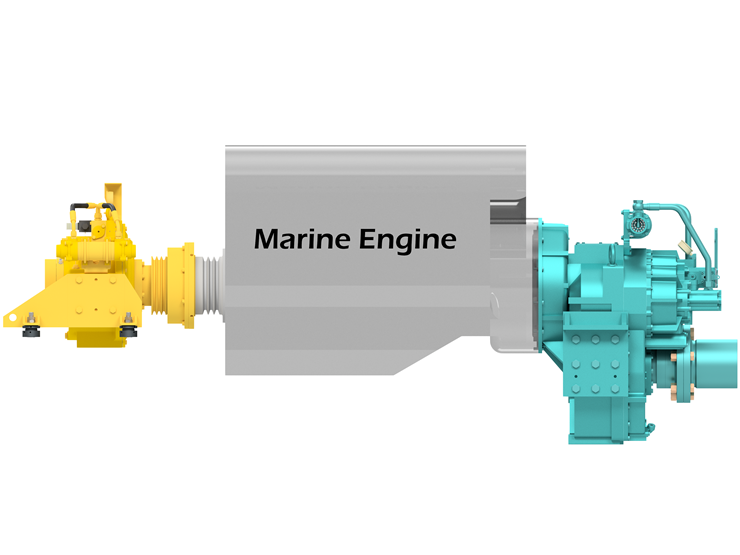

Mounting Example _ Auxiliary engine flywheel mounting type